Recent research by HSE found that 3D printers emit many particles of a size range that could potentially enter the airways and lungs. How can we control these emissions and develop the right respiratory protection for an invention that is expected to boom over the next decade?

Features

Risk in 3D

How can we control these emissions and develop the right respiratory protection for an invention that is expected to boom over the next decade?

Necessity, they say, is the mother of invention and that is certainly the case with Kora 3D. Impex Parts Limited, a company that has been supplying original equipment manufacturer (OEM) and aftermarket parts to the motor trade for over 20 years had been enjoying considerable success when changes to EU Motor Vehicle Block Exemption had seen demand for OEM parts increase rapidly and Impex was regularly receiving requests for parts that it was finding difficult to source externally.

The company decided to explore 3D printing as a solution and, finding it worked well, went on to own several commercially available 3D printing machines. Initial success soon turned to disappointment, however, when these 3D printing machines began regularly breaking down. Confident in both the skills of its engineers and the technology but frustrated that a better alternative did not seem to exist, the company decided to develop its own 3D printer machines and Kora 3D was born.

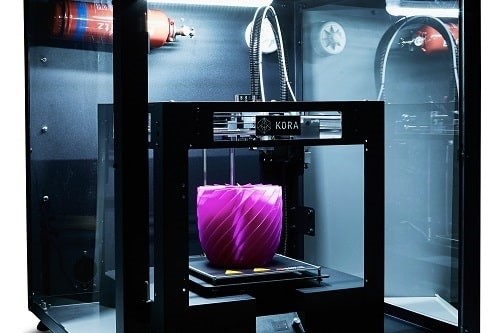

There is a risk that retrospective health issues from additive manufacturing may emerge in the coming years. Photograph: Kora 3D

There is a risk that retrospective health issues from additive manufacturing may emerge in the coming years. Photograph: Kora 3D

Within a year of launching, it received an invitation from the Health and Safety Laboratory (HSL), the research arm of the Health and Safety Executive (HSE), to participate in research concerning the emissions/VOCs (Volatile Organic Compounds) generated from all typical desktop 3D printers.

The contact from HSE was prompted by fears over the use of 3D printers in schools. The use of Fused Filament Fabrication (FFF) and Fused Deposition Modelling (FDM) 3D printers as part of the school curriculum has grown rapidly in recent years following a Department for Education funded pilot in 2012/13 to explore how 3D printing could be applied to the Science, Engineering, Technology and Mathematics (STEM) curriculum. However, concerns have consistently been raised over the safe use of the products and their impact on surrounding air quality.

The Consortium of Local Education Authorities for the Provision of Science Services (CLEAPSS), an advisory service supporting science and technology in schools, manages a helpline for schools and reported to HSE that it had been inundated with concerns from teaching staff and requests for a model risk assessment for the use of FFF/FDM style 3D printers as well as guidance around safe usage.

In response, the HSE formed a working group including HSE scientific and regulatory staff, Kora 3D, CLEAPSS and the British Standards Institution to identify the risks and develop a good practice guide for the safe use of FFF/FDM style desktop 3D printers.

Kora 3D committed to suspend sales of its own FFF/FDM style 3D printers until the research was complete. This was a huge commercial decision, but the company’s design engineers turned their attention to the development of a safety solution, manufacturing several filtration prototypes to address the identified concerns.

Four years later, HSE has now released its final report Measuring and Controlling Emissions from Desktop 3D Printers and the impact is likely to be far reaching. The report found that 3D printers emit many particles of a size range that could potentially enter the airways and lungs. The report also found that “emissions from FFF 3D printers are likely to be released into the general environment because many desktop printers have no form of control or particle capture.”

Worryingly, the research also found that some of the plastic filament materials used in the 3D printers were found to release vapours known to be hazardous to health when heated. During testing, it was found that placing the desktop 3D printer inside an enclosing hood with filtered ventilation reduced particle emission rates by 97 per cent. As a result, new guidance from CLEAPSS for schools was issued recommending the use of a “bespoke exposure control cabinet to cover each printer.”

If any organisation or business uses or creates substances or carries out processes which might cause harm to health, the law requires them to control the risks. Employers have legal duties under the Health and Safety at Work Act to ensure, so far as is reasonably practicable, the health, safety and welfare at work of all their employees.

This responsibility extends to other persons, such as pupils, students and visitors who may be affected by activities undertaken in the workplace. The Control of Substances Hazardous to Health Regulations (COSHH 2002) (1) requires employers to ensure that exposure is prevented or, where this is not reasonably practicable, adequately controlled and, as a result, the new guidance expects users to pay particular consideration to the location of the printer and recommends the use of an enclosing hood with filtered ventilation.

Working with HSE, Kora has now launched the Universal Safety Cabinet SC-01, which uses a specialist filter cartridge at the top of the cabinet to draw in clean air from the area in which is it situated and to remove a minimum of nine per cent of known filament micro size particles and potentially harmful emissions from the FFF/FDM 3D printing process.

3D printer Hot-End parts can reach temperatures in excess of 280 degrees celsius [°C] and usually include several exposed moving parts, so the lockable cabinet fully encases the printer to safeguard users from any potential burns or entrapment of fingers, hair etc., while an optional heat sensor, automatic fire extinguisher and LED lighting provide additional user protection.

It is believed that the use of additive manufacturing, including in aerospace, medical, transportation and energy among other sectors, will continue to boom over the next decade, albeit with tighter safety controls and laws protecting individual users.

There is the risk that retrospective health issues from additive manufacturing may emerge in the coming years, however the new guidance from HSE should ensure safe use going forward.

Measuring and Controlling Emissions from Desktop 3D Printers report here

FEATURES

How to mitigate the hearing loss cost escalation tsunami

By Peter Wilson, Industrial Noise and Vibration Centre (INVC) on 06 February 2026

Employers need to adopt the latest and most effective noise risk evaluation and management measures, or face rapidly-rising compensation claims for noise-induced hearing loss at work.

Young drivers and work-related road risk: why employers must act now

By Simon Turner, Driving for Better Business on 06 February 2026

Young drivers have a higher risk of being involved in road collisions due to factors such as their inexperience, so when employing them to drive for work, it is vital they receive the right support to help them grow into safe professionals behind the wheel.

Financial stress: why and how it affects workplace safety

By Chloe Miller, freelance writer on 06 February 2026

Financial worries can lead to cognitive impairment that increases the risk of workplace accidents, so it’s essential employers provide financial education and confidential support for workers who may be struggling with problems like debt and unexpected living expenses.