A collaborative investigation into dust exposure levels during road planing works on the M25 motorway led to dust levels being cut by half – and some vital lessons for the highways maintenance industry on preventing respiratory disease.

Features

You only have two lungs

Working in construction can be a dangerous business. Every year in Great Britain the Health and Safety Executive estimates that 4,000 construction workers die from diseases caused by workplace exposures. That’s 100 times as many deaths from ill health as accidents! And the vast majority of these are respiratory disease deaths caused by long-term exposure to dusts. Many construction tasks produce dust exposures, but you only have two lungs. So how does dust affect them?

Most deaths from ill health in construction are from respiratory disease caused by long-term exposure to dusts. Photograph: Connect Plus

Most deaths from ill health in construction are from respiratory disease caused by long-term exposure to dusts. Photograph: Connect Plus

How breathing works

We usually take breathing for granted, but this life-sustaining process can be very vulnerable to certain working environments.

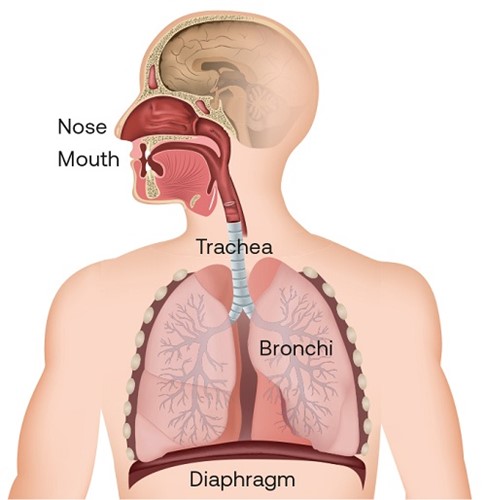

Breathing is how we get oxygen into our bloodstream and expel carbon dioxide. Air enters through our nose and mouth and travels down to the lungs through a tube called the trachea. This splits into progressively smaller tubes called bronchi. It looks like the branches of a tree. This system is known as the upper respiratory tract. Under our lungs is the diaphragm muscle that helps them expand and contract.

At the very end of the ‘tree branches’ are the alveoli sacs where oxygen and carbon dioxide are exchanged with the bloodstream across a membrane less than one micron thick. Inhalable dust is the fraction of breathable dust up to 100 microns in size that gets trapped anywhere in the upper respiratory tract. This is the dust you can see.

Air enters through our nose and mouth and travels down to the lungs through a tube called the trachea. Photograph: iStock

Air enters through our nose and mouth and travels down to the lungs through a tube called the trachea. Photograph: iStock

Respirable dust is the dust you can’t see; with particles less than 10 microns in size. These get right down to the alveoli region, and like clouds of tiny razor blades, they begin scarring the tissues.

Occupational lung diseases

Inhaling respirable crystalline silica (RCS) dust causes silicosis, a lung disease that causes severe breathing problems and increases the risk of lung infections. Metal dusts can cause similar lung diseases. Inhalable dust can also cause chronic obstructive pulmonary disease (COPD) – a worsening inflammation of the airways – and wood and asbestos dusts can cause cancer.

These are all debilitating and often fatal diseases for which there are no cures. Dust can also cause irritation and allergic reactions like occupational asthma.

‘But, we use dust masks’

So often respiratory protective equipment (RPE) is our first port of call, when it should actually be our last line of defence. Of course, RPE will have a part to play in many safe systems of work, but if it’s your only exposure control method, you probably have a major problem.

Steve Perkins: "So often respiratory protective equipment (RPE) is our first port of call, when it should actually be our last line of defence."

Steve Perkins: "So often respiratory protective equipment (RPE) is our first port of call, when it should actually be our last line of defence."

RPE, particularly disposable dust masks, can fail in many ways, because its effectiveness depends strongly on human behaviour. For example, RPE may be:

- Not worn, or worn incorrectly

- The wrong type

- Not fit tested to ensure it correctly fits the individual user

- Worn by someone who is not clean shaven (which can prevent the mask properly sealing to the face, allowing in contaminated air)

- Contaminated due to poor maintenance.

All of this can actually lead to even higher dust exposures as people think they are protected when they’re not.

It’s worth remembering that respirable crystalline silica (RCS) particles are under 10 microns in size. Male beard hairs are on average 100 microns in diameter. That means they’re between 10 and 100 times larger than RCS. So, a mask worn over beard hair will leak silica like a sieve at the edges!

Using respiratory controls effectively on the M25

Our award-winning work with Connect Plus (which manages and operates the M25 road network), and the M25 supply chain in the highways sector has highlighted the critical importance of using respiratory controls effectively – even when thinking about engineering controls further up the hierarchy of control (see the panel below). The lessons from our occupational hygiene investigation into road planing dust control are applicable to dust exposure control in any sector.

Asphalt road planing case study

Road surface renewal and maintenance is a ubiquitous task across the motorway network and beyond. It is nowhere more critical than on the M25, the busiest motorway in western Europe.

If you’ve ever witnessed surfacing operations you will no doubt have marvelled at the speed and professionalism of the operation, which is a highly choreographed ‘ballet’ of civil engineering in action. But you will have also noticed how dusty the works can be. Even though it’s outdoors, these exposures can be a health risk to workers. So, how serious is that risk and what more can be done to control it?

As part of the ongoing M25 Healthier Highways initiative, an exposure assessment and control improvement project was undertaken to answer these questions. Healthier Highways is a collaborative initiative led by Connect Plus working in partnership with Steve Perkins Associates, to transform health culture in the M25 supply chain.

From a health perspective, surfacing works are challenging for a number of reasons: they are both temporary and mobile work sites; works are conducted at night; works involve a variety of contractors arriving and leaving at different times; and there is a range of potentially serious health exposures. As one framework manager responsible for maintenance works on the M25 put it, “if we can make a health difference here, we can make a difference anywhere!” Following an initial site visit it was agreed to conduct personal exposure monitoring on the crew of the planer, who were identified as most at risk from dust exposure.

Personal exposure monitoring

For asphalt planing (pictured below), RCS levels were found to be relatively low, and inhalable dust levels were significant, but not excessive.

Asphalt planing in action. Photograph: Steve Perkins Associates

Asphalt planing in action. Photograph: Steve Perkins Associates

However, respirable dust exposures that penetrate into the deep lung, potentially causing the most serious health issues, were found to be high, with levels approaching or above the Institute of Occupational Medicine’s (IOM’s) recommended exposure limit of 1mg/m3. It was clear that action needed to be taken to improve dust exposure control.

Connect Plus has created an innovative and highly collaborative community culture on the M25. We leveraged this to form a Surfacing Supply Chain Working Group (SSCWG) to take the issue forward. The group was led by Steve Perkins Associates and made up of senior representatives from Tarmac and Milestone (framework contractors), NRP, Toppesfield and Simms (surfacing contractors) and Wirtgen (the planer manufacturer).

Road planer dust engineering controls

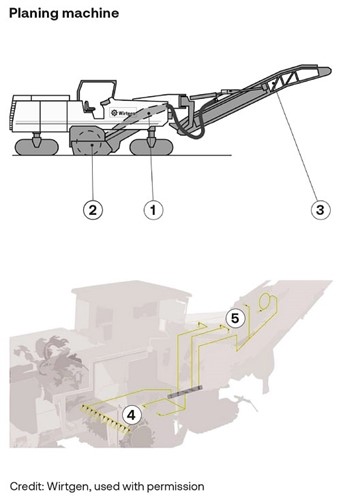

Large modern planing machines of the type used on the M25 (see diagrams below), have two types of engineering control to address dust exposures.

First, a vacuum control system (VCS) (1) that extracts dust from the planer drum housing (2) to deposit it on the conveyor belt (3) for transport to the tailings lorry. Second, a water spray system that primarily acts to cool the drum tools, but also damps down dust in the drum housing (4) and on the conveyor belt (5).

Planing machine. Illustration: Wirtgen

Planing machine. Illustration: Wirtgen

Discussions both within the SSCWG and with workers on site revealed some interesting perceptions when it came to using the water spray system. It appears that across the planing industry, not just on the M25, there is a strong perception of a requirement to minimise water use during planing. A number of reasons for this were cited, including the need:

- For tailings (asphalt debris) to be as dry as possible prior to recycling

- To conserve water as an environmental resource

- To keep the carriageway as dry as possible to facilitate relaying

- To avoid delay and cost to the job to refill from a separate water bowser.

The net result of these perceptions is that the water spray to the conveyor belt is often turned off altogether! This drastically reduces the effectiveness of the dust control. And, surprisingly, everyone from operatives to senior managers thought they were doing the right thing.

The SSCWG provided an ideal forum in which to investigate these perceptions and identify that none of them were an issue. For instance, it transpires that asphalt recycling plants place no specification on the water content of tailings and actually store them outside in all weathers before remixing them.

Also, M25 asphalt planing is carried out at night in short timeframes to minimise road closures. This means a full, large planer water tank will not need refilling even if the maximum water spray is used continually. In addition, we were able to establish that maintenance of the VCS dump valve and fan inspections tended to be less frequent than the manufacturers’ recommendations, adding to the reduced effectiveness of the dust controls.

Proving the effectiveness of water spray

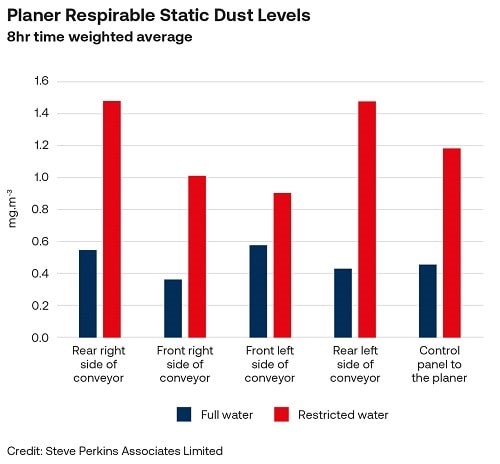

In order to conclusively prove the effectiveness of the water spray system controls, further static exposure monitoring tests were conducted over three nights with dry weather conditions with both Tarmac and Milestone. Dust samplers were placed at different points on the planer, rather than on workers to reduce measurement variability.

Restricting the water spray just to the planer drum housing (i.e. no water spray to the conveyor) resulted in an average increase in respirable dust levels of 120 per cent. This means that full water spray to the conveyor belt more than halves the dust levels in the vicinity of the planer, as shown in the graph below.

The difference in dust levels between the use of full water spray at all points and no water spray on the belt could also easily be observed visually during operations.

The SSCWG agreed that all M25 planing works will now be carried out with contractors ensuring that water flow and the extraction fan are operated and maintained in accordance with the manufacturer’s recommendations.

We have briefed the workforce widely on these results through a range of channels. Connect Plus and Connect Plus Services (who maintain the M25 network), have introduced checks on the use of water for planing to ensure that it is carried out in accordance with the manufacturer’s recommendations. Tarmac and Milestone now ensure checks are made with their planing crews and contractors on the correct water spray usage and fan maintenance. Wirtgen is working on guidance for planer operators to ensure the local exhaust ventilation (LEV) system of the planer fan and ducting is adequately maintained and tested.

The SSCWG was a great example of how collaborative working combined with applied occupational hygiene can achieve a positive health change – both for the M25 road maintenance workforce and the wider global road maintenance workforce. These results have wider application across the planing industry and we have shared them with planing trade associations in both the UK and Europe.

Transferable lessons for effective use of engineering dust controls

1. Understand what controls you already have, how they work and what you need to do to maintain them properly

2. Take time to check on site and talk to operatives to understand if or how they’re actually used in practice. Just because a Risk Assessment and Method Statement (RAMS) says something does not mean that’s what’s actually happening!

3. If you discover problems in the use of engineering dust controls, focus on removing the barriers. Make it easy for people to do the right things

Regularly maintain controls – for example, make sure LEV systems are functioning at their specified efficiency

4. When appropriate, measure workers’ dust exposures to verify that the controls are achieving the outcomes they’re supposed to

5. Train users both on what they need to do to use the engineering dust exposure controls effectively, but also why it’s important they do this. People need to have the reasoning explained to them and be given the opportunity to ask questions about it.

Steve Perkins is the managing director of Steve Perkins Associates Limited, an occupational hygiene and health consultancy specialising in strategic workplace health solutions. Contact him at:

Steve Perkins will be giving a presentation at the SHW Live exhibition in Farnborough, Hampshire, on 28–29 September, on ‘Changing Workplace Health Culture –Healthier Highways on the M25’. He will be joined by Elaine Gazzini, technical and programme director at Connect Plus (M25).

See: safetyhealthwellbeing.live

FEATURES

Underpinning safety training with neuroscience for long lasting impact

By SSE Active Training Team (ATT) on 30 November 2025

A behavioural safety training programme developed by Active Training Team for energy provider SSE has been carefully designed with neuroscientific principles in mind – resulting in a prestigious industry award for Best Training Initiative in 2024.

Why a painted line will never be enough

By UK Material Handling Association (UKMHA) on 20 November 2025

Businesses that operate material handling equipment like forklifts are being urged to submit accident and near miss details to a new confidential reporting portal so the industry can identify what needs to be done to improve safety standards.

Why workplace transport training is changing in 2026 and what it means for employers

By AITT on 26 November 2025

New workplace transport training categories due in January mean it is essential to ensure operators of material handling equipment have the necessary training for the exact type of machine they use, and accredited training providers are an ideal source of advice and conversion training.