Under Health and Safety Executive (HSE) guidelines employers must ensure that lifting equipment – such as forklifts, telehandlers and reach trucks – can be used safely and without risk of injury.

Features

Let’s examine this

To comply that means having both the lifting and driving mechanisms inspected at least once a year as part of a Thorough Examination in line with LOLER (Lifting Operations and Lifting Equipment Regulations 1998) and PUWER (Provision and Use of Work Equipment Regulations 1998).

Don’t risk half measures

Sadly, many inspection providers do not offer consistent levels of service. As many as three out of every four inspections of materials handling equipment address LOLER – i.e., only the lifting mechanism – ignoring the remainder of the truck.

The confusion arises because many people use the terms ‘LOLER’ and ‘Thorough Examination’ interchangeably, as if they were the same thing. They aren’t.

To overcome the problematic variation in the standard of examination providers, CFTS was developed by BITA (British Industrial Truck Association) and the FLTA (Fork Lift Truck Association) in consultation with HSE.

CFTS is the national accreditation body for Thorough Examination and Safety Inspection of materials handling equipment – and the only industry-recognised, independent scheme in the UK.

With CFTS, accredited members will provide a qualified, accredited Thorough Examination engineer, known in the industry as a Competent Person, who can carry out a full inspection in line with the LOLER and PUWER regulations.

To help employers understand how to meet their responsibilities and avoid falling foul of the law, we have pinpointed a few key areas to be aware of:

- Scope: A CFTS Thorough Examination covers 33 different parts and systems in line with LOLER and PUWER, as well as a further 34 checks specifically for any attachments

- Tools: Does your examiner carry the equipment necessary to conduct the inspection thoroughly? Most CFTS examiners use equipment such as

an A-frame ladder to inspect the top of the truck’s mast, a trolley-jack to inspect brakes and steering, and an industry-recognised chain gauge (rather than a steel ruler or tape measure) for accurate assessment

of chain elongation - Competence: Examiners should be trained specialists in materials handling equipment and be competent to apply real-world judgements based on the truck rather than theoretical projections. CFTS-accredited examiners follow a Quality Assured Procedural Code that requires them to meet stringent standards and undergo regular refresher training

- Timing: Is your equipment being examined on the correct schedule? According to the type of truck and the application it could need testing once or twice a year, or even more frequently

- Documentation: Do you receive the appropriate documentation to certify, beyond doubt, that everything has been carried out by an accredited examiner? A CFTS-accredited examiner will issue:

- A Report of Thorough Examination

- An itemised checklist showing what has been inspected and comments made

- A certificate of compliance to keep with the truck’s documents

- A sticker placed prominently on the truck showing the day, month and year that the next Thorough Examination is due

- A sticker to show when repairs must be completed by.

How often are Thorough Examinations needed?

Many work equipment owners are unsure as to how often Thorough Examinations are required, and this mistake can lead to equipment failure and workplace accidents.

Recently, a fencing manufacturer was fined £35,000 after a fatal incident on site. A telescopic handler was being used to move timber, when the load was lifted too high and the truck tipped over, knocking stacked timber onto a member of personnel, resulting in his death.

The subsequent HSE investigation found the telehandler safety device – designed to stop loads being lifted too high – had not been functional for a long period. The owner had not ensured that the machine was properly maintained or thoroughly examined.

As instances like this show, it is vital that equipment be regularly assessed

in order to identify faults, before they lead to accidents with life-changing consequences – much in the same way that cars need regular MOTs.

But what does ‘regular’ mean in practical terms?

The truth is that vehicles can have different inspection intervals. While some do need to be inspected only once a year, others may need a Thorough Examination more frequently.

A CFTS-accredited Competent Person can help determine an inspection schedule based on factors such as the truck type, attachments, operating environment and usage – giving you complete peace of mind that your truck is being checked regularly enough.

To gauge how often Thorough Examinations are required, take this quick CFTS quiz.

Following industry guidance

CFTS uses procedures and documentation that are totally compliant with the industry guidance, Thorough examination & safety inspections of industrial lift trucks, known as GN28. This ensures that all CFTS Thorough Examinations and Safety Inspections are conducted in line with legal requirements and industry standards.

The guidance enshrined in GN28 has recently been updated and enhanced. However, it is important to note that the laws for the Thorough Examination and Safety Inspection of lifting and materials handling equipment under LOLER and PUWER have not been changed.

If you are responsible for overseeing handling operations, you will need to make sure you are up to date with these changes, as they affect many different aspects of Thorough Examination for a wide range of equipment.

Here are some of the key points in the new GN28:

- For lorry-mounted trucks where the operator can be lifted with the truck as part of the mount/dismount sequence, a Thorough Examination is necessary at least every six months (more frequently if conditions require – for example, corrosive environments)

- Similarly, attachments not permanently mounted to the truck will also require examination at least every six months

- In situations where an exceptional event has occurred – such as an impact or overload – an additional Thorough Examination is required before the equipment is brought back into service

- If the Competent Person carrying out the inspection is unable to complete a Thorough Examination due to a serious defect of the lifting parts, then they must inform the relevant enforcement authority

- Where fitted, operator assistance systems, safety cut-offs and speed reductions must be working correctly

- Creep of the load handling system should be assessed with a representative load and the hydraulic fluid at the normal working temperature. Where there is doubt further testing should be specified on the report of Thorough Examination

- Parking brake performance can be verified by ensuring that it holds the truck stationary on the maximum operating site gradient when carrying a representative load

- Where there is a defect or imminent failure in the lifting equipment involving a risk of serious injury – for example, chain or fork wear beyond replacement limits, or a missing or defaced capacity/data plate – the examiner must send a copy of the report to the relevant enforcement authority as required by LOLER.

Inspecting attachments and MEWPs

Although many equipment owners and operators know their responsibilities when it comes to their lift trucks, there is still a lot of confusion about the inspection requirements for attachments (such as safety cages, bale and barrel clamps) and MEWPs (mobile elevating work platforms, such as scissor lifts or ‘cherry pickers’).

Remember, if lifting attachments are not permanently fitted – then they must receive a separate Thorough Examination to ensure they are safe and in good working order.

With MEWPs, the law is also quite clear. Under the LOLER regulations, a MEWP should undergo a Thorough Examination at least every six months to ensure the equipment is not faulty and doesn’t pose a risk to your staff.

The biggest problem regarding inspections of these types of equipment is that of specificity. Many inspection providers use a generic checklist when assessing attachments and MEWPs. That is not best practice and could leave you exposed to accidents, damage, disruption and prosecution should things go wrong.

When conducting an examination, it is vitally important that the documentation includes a full set of checks specific to the equipment.

CFTS members use dedicated checklists tailored to the type of equipment – be that lift trucks, attachments or MEWPs. This ensures all electronic, hydraulic and mechanical components are working correctly and safely. For example, a CFTS attachment examination will: assess the security of attachment mounts; test winch and chain brakes; check chain and sling wear; inspect damage and check wear on plates and warning signs.

This in-depth inspection criteria is assured in CFTS-accredited companies by a stringent audit process.

Stay compliant, stay safe

Thorough Examinations may be the difference between a safe business and an unsafe one. As we have seen, accidents relating to mechanical faults with lifting and materials handling equipment persist even today, but there is never an excuse for not meeting your legal obligations.

CFTS members remained available throughout the pandemic to provide Thorough Examinations and support owners in maintaining inspection schedules. However, if equipment was stood down for long periods during the past year, it will require a Thorough Examination before reintroduction to service to ensure that it is still in a safe condition.

There are more than 600 CFTS-accredited depots nationwide, so it’s easy to find a Thorough Examination provider near you.

Geoff Martin is Chairman of CFTS

Find out more at: www.thoroughexamination.org/find-an-accredited-examiner

FEATURES

5 trends to watch in the safety sector in 2025

By David Head, Draeger Safety UK on 19 March 2025

Dräger’s annual Safety and Health at Work Report provides a useful insight and snapshot into the views of employees and managers on safety in UK workplaces. This year’s report suggests employers need to increase and refine their efforts in areas such as employee mental wellbeing, more structured safety training and greater use of digital and connected safety technology.

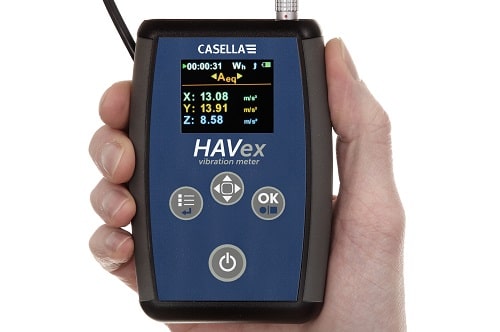

Get a hold on HAVS, before it’s too late

By Tim Turney, Casella on 18 March 2025

Employers may need to carry out measurements of hand-arm vibration from hand-held tools and machinery to identify if workers are at risk of debilitating and permanent damage to their fingers, hands and arms, but it’s essential the measurement equipment is used in the correct way.

The UK Hearing Conservation Association: how we work to promote the protection of the nation’s hearing health

By Leah Philpott, member, UKHCA At Work Group on 14 March 2025

The UK Hearing Conservation Association is a multi-disciplinary association that strives to prevent damage to the nation’s hearing health and other noise-related health conditions through a combination of practical, evidenced and cost-effective campaigns, awareness-raising activities and best-practice advice. It is therefore a great forum for those wishing to keep abreast of the latest developments around hearing health – both in the workplace and in recreational settings.