It is 50 years this year since I started an engineering apprenticeship with Black Country-based GKN Sankey, to be told upon walking into a very noisy high-speed blanking and piercing shop (with power presses running at 400 blows per minute), “don’t worry son, you’ll get used to it”.

Opinion

Why we need to harness new technology to prevent noise-induced hearing loss

The good news was that earplugs were readily available from strategically placed dispensers. As a new starter, I got a hearing test from the on-site occupational nurse, but there was zero training on the use of the plugs themselves or any checks on how well they were fitted.

This is why the hierarchy of hazard controls today states that personal protective equipment (PPE), often a first line of defence, is the least effective and needs the most supervision, but certainly not of the “don’t worry son, you’ll get used to it” kind!

Photograph: iStock

Photograph: iStock

In further bad news, I recall seeing very expensively engineered acoustic enclosures with their doors routinely left open while presses were running, and workers, including managers, with their hearing protectors around their necks!

So, as Chris Steel, specialist noise and vibration inspector with the Health and Safety Executive (HSE) says, such ‘CUFF’ issues for personal hearing protection (like earmuffs and earplugs) are really important, namely:

- Condition

- Use (all the time when in noise)

- Fit

- being fit for purpose. having an appropriate SNR value.

All of the hearing protection shown in very poor condition in the photograph below (courtesy of Chris), was removed from different workplaces by HSE inspectors or their scientists.

Poor quality hearing protectors found during HSE inspections. Photograph: Chris Steel, HSE

Poor quality hearing protectors found during HSE inspections. Photograph: Chris Steel, HSE

Noise-induced hearing loss remains a problem

Since my apprenticeship during the mid–late 1970s, we have had not one, but two rounds of noise legislation. In the meantime, sadly that factory has long since gone, along with much of the British manufacturing industry of that time, as well as most of my hair, waistline and some of my hearing!

OK, the ageing process probably accounts for the latter decline but there could also have been a contribution from my time in industry (although unlikely in my case). However, we know that workers in mining, shipbuilding and heavy industry, to name but three, suffered hearing loss in the past, and the military are still suffering hearing damage today. In fact, the military is another sector I’ve worked in, providing hearing protection that also had communication capabilities.

It is repeated exposure to high noise levels over time which can lead to irreparable noise-induced hearing loss (NIHL). Yet it is wholly avoidable and is still the world’s number one occupational disease – despite the evidence of cause and effect dating back in the UK to the shipbuilding industry of the Clyde in the 19th Century.

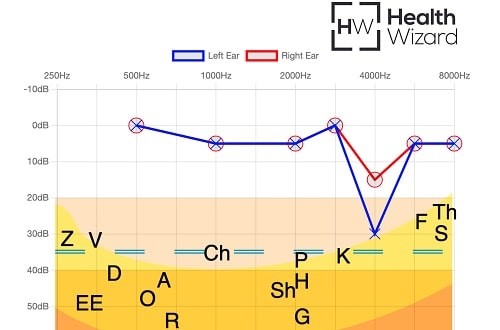

Source: Health Wizard

Source: Health Wizard

Having to shout to be heard a metre apart is a sure sign of a noise problem, as is the resulting characteristic dip in an audiogram at 4000Hz if NIHL is present (see the example audiogram above, courtesy of Health Wizard).

You can argue the toss about the benefits of a lagging indicator after hearing damage has been done, but this is a recent, real-world audiogram from the food processing sector.

Let us say for the sake of argument this was my audiogram and I put in a claim via a no win-no fee solicitor. Who is going to be liable after all this time? This is where the Employers’ Liability Tracing Office (ELTO), set up by the insurance industry, comes into its own with more than 25 million insurance policies spanning more than 100 years – important because of the lag between exposure and diagnosis.

The ELTO’s 2022 annual report shows the rank of claimant searches for industrial exposure-based diseases, and guess what? NIHL tops the list by a big margin.

But the damage could equally have been caused by exposure to recreational noise outside of work; from strutting one’s stuff at the disco à la John Travolta (showing my age there), or perhaps clay pigeon shooting or motorsport. Indeed, just listening to music or gaming on headphones for long periods is potentially as damaging as a noisy factory.

The RIDDOR riddle

Therein lies the RIDDOR Riddle, which I wrote about last year when HSE was undertaking a post-implementation review (PIR) of the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 (RIDDOR) reporting legislation. HSE was considering whether the list of occupational diseases affecting workers that must be reported to HSE by employers under RIDDOR should be expanded.

Neal Hill is a consultant and member of the UK Hearing Conservation Association (UKHCA)

Neal Hill is a consultant and member of the UK Hearing Conservation Association (UKHCA)

In a previous review of RIDDOR, hand arm vibration syndrome (HAVS), a painful and debilitating condition caused by work with vibrating hand-held or hand-guided tools, had made the cut and was therefore included in the list of RIDDOR-reportable occupational diseases. HAVS ranks number 10 in the ELTO list of claimant searches for industrial exposure-based diseases on the ELD (see the table), while NIHL is number one. However, the contribution to NIHL from workplace exposure alone is much harder to pin down and, perhaps partly for this reason, NIHL is not on the list of RIDDOR-reportable diseases. Better luck next time, maybe?

Even more reason, therefore, for employers and industry to adopt a new approach to preventing noise exposure at work (and therefore NIHL), using technology-based, connected solutions as we enter the 4th Industrial Revolution. This means adopting approaches such as:

- A risk assessment backed by noise measurements incorporated into wearable technology

- Hearing protector fit testing, as championed by the UK Hearing Conservation Association (UKHCA) and the British Safety Industry Federation (BSIF), with perhaps this even made mandatory, as it is for respiratory protective equipment

- Automated hearing protection wearer compliance monitoring

- Routine workplace health surveillance through regular field audiometry, which costs a few tens of pounds per employee and can be supervised remotely.

Recognising these trends, the British Standards Institute (BSI) convened a SMART PPE and Workplace Wearable Technology Roundtable meeting in January 2024 at their laboratory in Hemel Hempstead. Here, professionals from various industries – including PPE manufacturers, academia and government – explored the realm of wearable devices. Their aim was to enhance personal wellbeing and workplace safety through tailored solutions that facilitate data collection for predictive and preventive risk management.

With a similar motivation for data, the UKHCA and the Society of Occupational Medicine jointly put out a position statement on the implementation of HSE Noise Health Surveillance Guidance in May 2023 which references HSE publication L108, Controlling noise at work, which itself is well worth the £22 for a hard copy (or free in PDF format from HSE’s website). This covers:

- Part 1: Legal duties of employers concerning noise at work

- Part 2: Management and control of risks from noise

- Part 3: Practical examples of noise control

- Part 4: Hearing Protection

- Part 5: Health surveillance for hearing damage

- Part 6: Selecting quieter tools and machinery.

However, the world of work is changing, with many workers using headsets for communication purposes in environments like warehouses and noisy call centres, and I predict that there will a tsunami of future NIHL claims from these sectors without suitable interventions.

So, as the current legislation nears its 20th anniversary – and technology has made leaps and bounds – it is time for more joined-up thinking to eradicate NIHL. And I look forward to playing my part as a BSI standards committee member.

Neal Hill is an independent marketing and product management consultant with over 40 years’ experience in noise measurement and hearing protection. He sits on the BSI PH/7 hearing protection standards committee as the UKHCA’s nominated representative.

Contact him at: linkedin.com/in/neal-hill-89b16211/

OPINION

Alcohol – the negative impact on work and workplaces

By Dr Jamie O’Halloran, IPPR on 02 January 2026

New IPPR research shows that most employees expect their employer to play an active role in reducing alcohol harm. Senior staff, in particular, believe employers have an even greater responsibility. Yet in practice, many employees say they do not see their employer taking meaningful steps to minimise harm.

Beyond 2025: The journey towards a safer world

By Mike Robinson FCA, British Safety Council on 22 December 2025

As 2025 draws to a close, we reflect on a year of success and safety. It also allows us to look forward to the coming year, recognising that with each new year comes the unbridled hope and opportunity to create the safest year in human history for the workers of the world.

How to create a neuroinclusive workplace

By John Robinson, Schofield Sweeney on 09 December 2025

The modern workplace is a diverse environment. Most workforces will be made up of individuals representing the majority of the groups protected under the Equality Act 2010.